Precision with capacity.

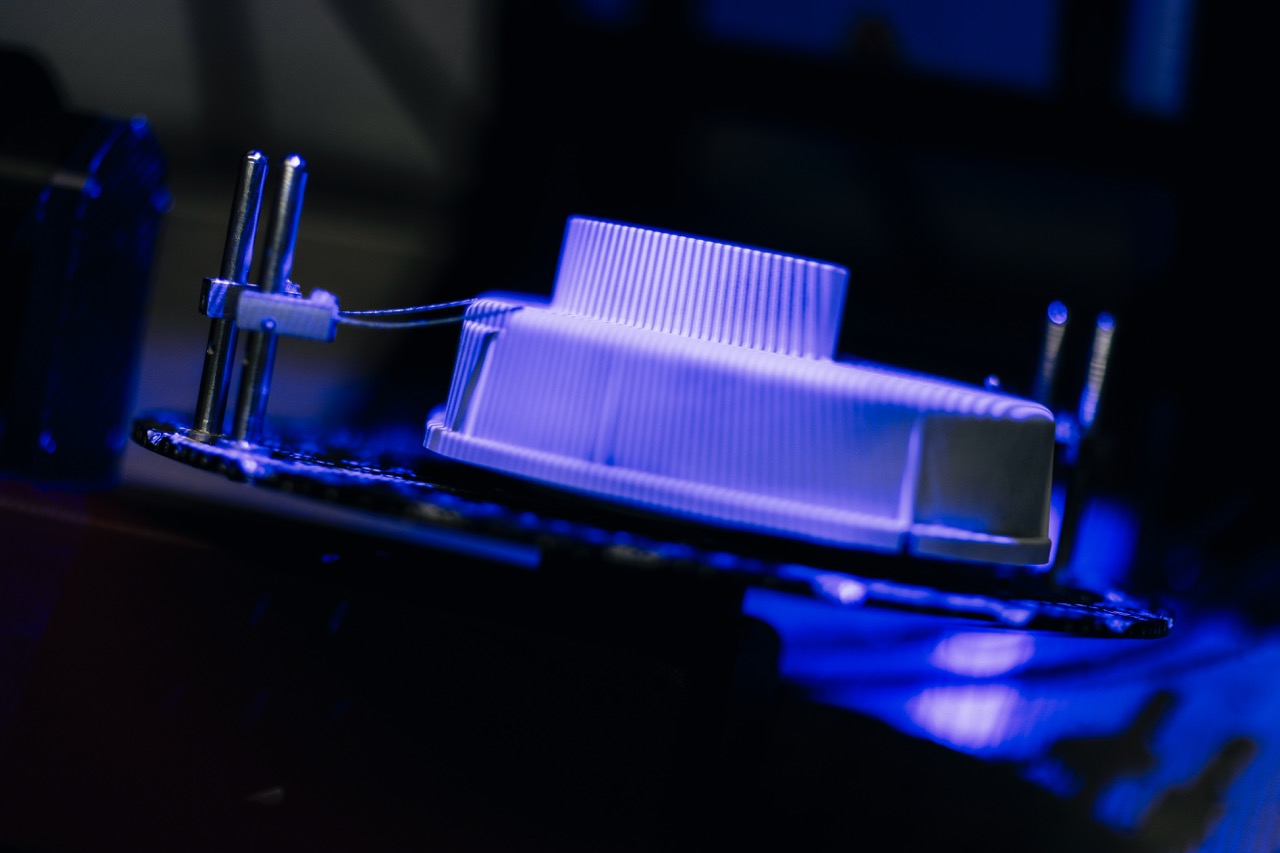

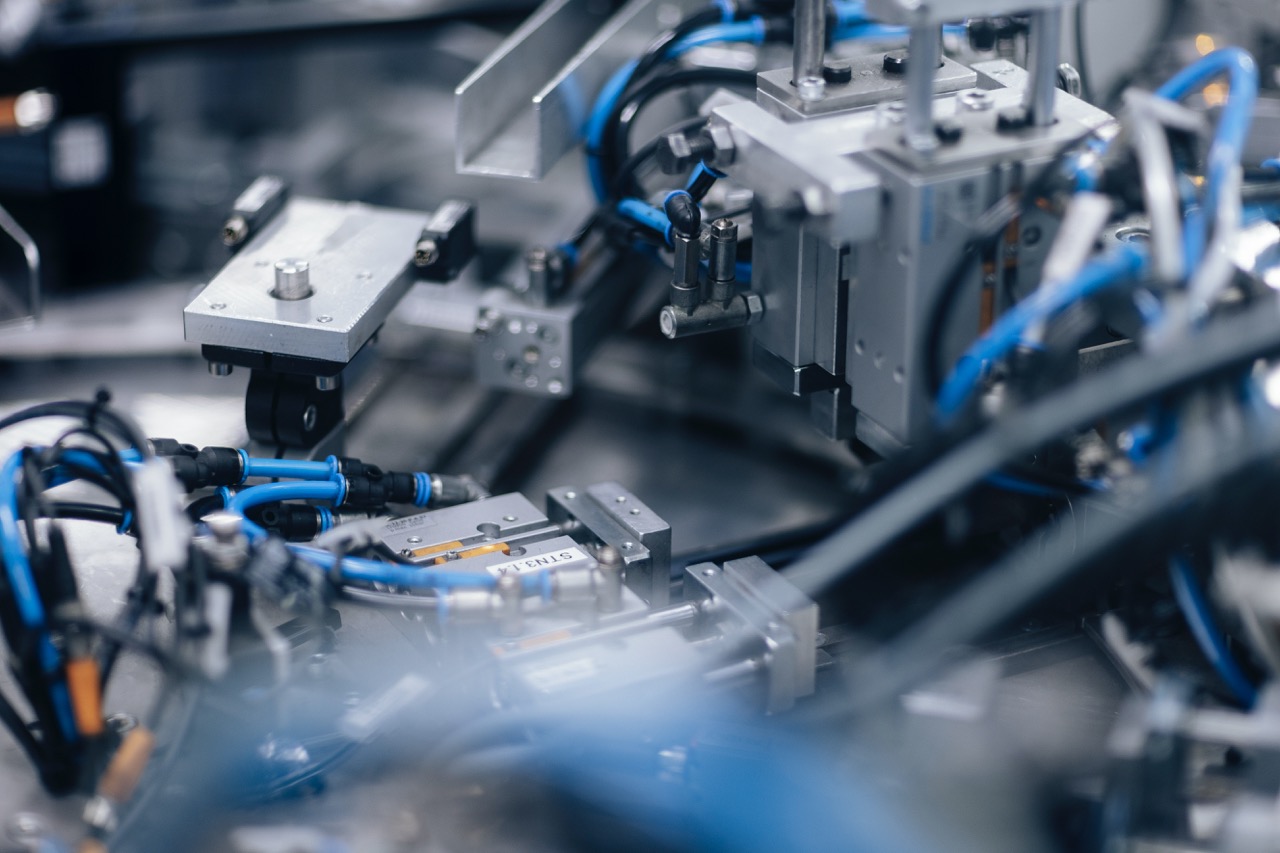

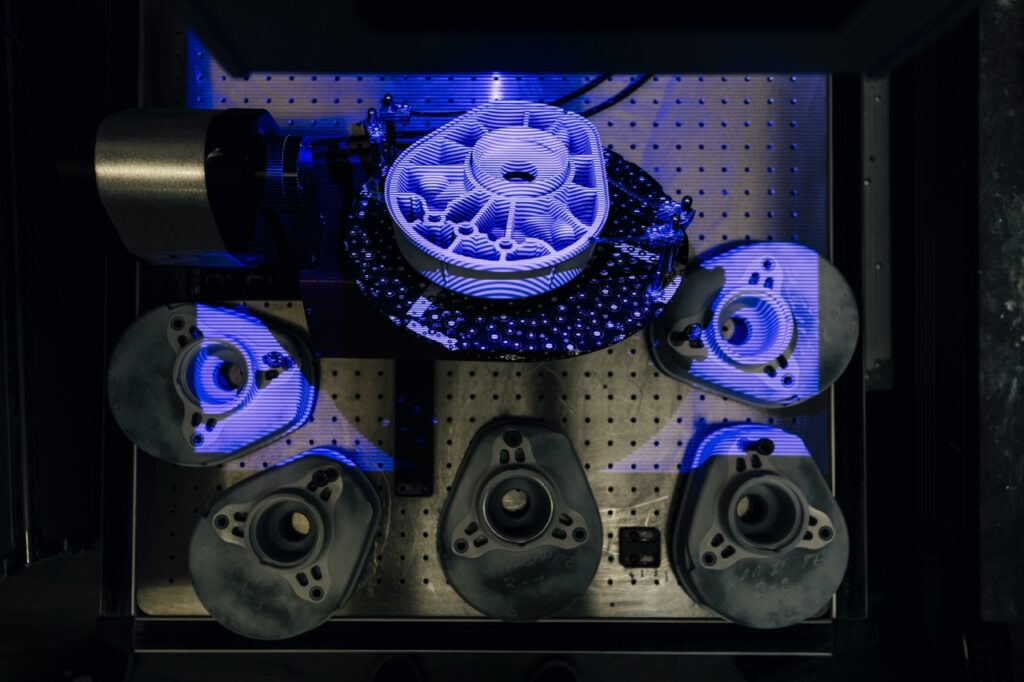

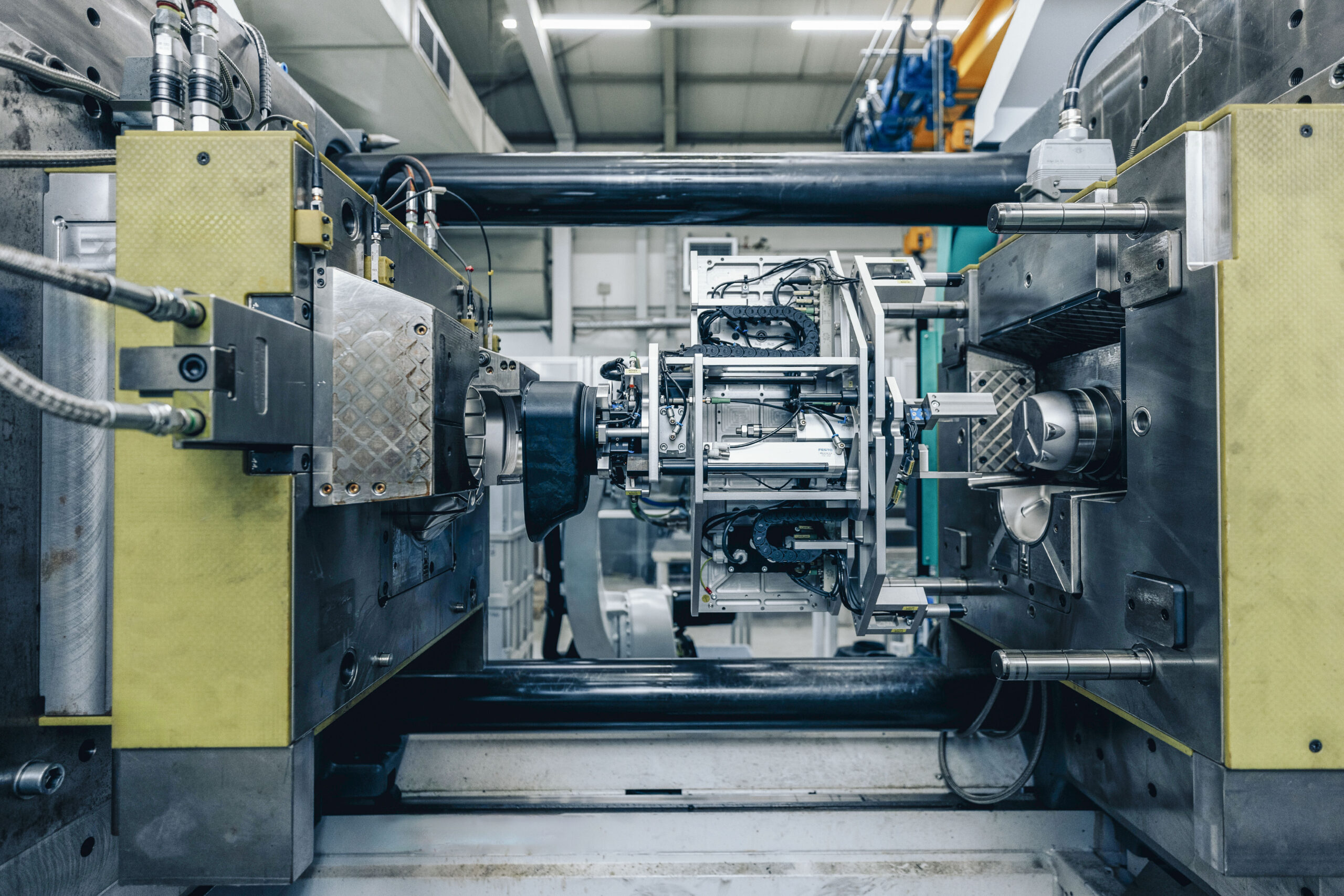

AGRODUR has a modern, high-capacity precision production facility that enables us to manufacture your highly complex technical functional parts from almost all thermoplastics and thermosets. Our machinery includes 100 injection moulding machines with clamping forces from 150 kN to 6500 kN as well as 10 automatic presses with up to 6000 kN, which are designed for processing more specialised thermosets. Class 7 and 8 clean rooms in accordance with ISO 14644 are available for applications that require even higher standards of cleanliness and hygiene.

Customised parts.

Processes made to measure.

In addition to ideal conditions during actual production, AGRODUR also offers you optimum conditions for all the preceding planning steps: a process chain customised to your ideas and requirements, which begins with initial development and material selection, continues through design, construction and prototyping and culminates in additive manufacturing and series production in state-of-the-art systems – the pinnacle of your satisfaction.

Transparent across the entire production line.

At AGRODUR, you have a dedicated contact person at your side throughout the entire production process – from your enquiry to series production. A multidisciplinary team of plastics experts who monitor the cost-effectiveness, quality and sustainability of your project and make any necessary adjustments. You can rely on this – or see for yourself: our regular project progress reports ensure maximum transparency in the planning of your products.